3 Ways to Use Less & Save More When Using Wiping Products

In many cases, less is more. This is especially true in the case of wiping products. Overuse is rarely a personnel issue and is typically the result of inefficient processes. Selecting the wrong wiping products for your business can lead to overuse, poor performance and unnecessary waste. For General Managers and Site Managers seeking to improve sustainability and operational efficiency while reducing costs and resource consumption, the solution breaks down to three key components:

- The right wipers

- The right put-ups

- The right locations

Follow these steps to select the right wipers for the job and start using less.

- The Right Wipers

The best wiper for each application is not necessarily the strongest, the cheapest or the one with the most sheets per case. The best wiper is the one that gets the job done fastest while using the fewest sheets.

In addition to obvious product costs, using more sheets also creates hidden expenses including increased transportation costs, additional storage requirements and more frequent waste management needs. As bins fill up faster, staff needs to empty them more often. When staff needs to empty them more often, this can potentially require your business to schedule more frequent waste collection services.

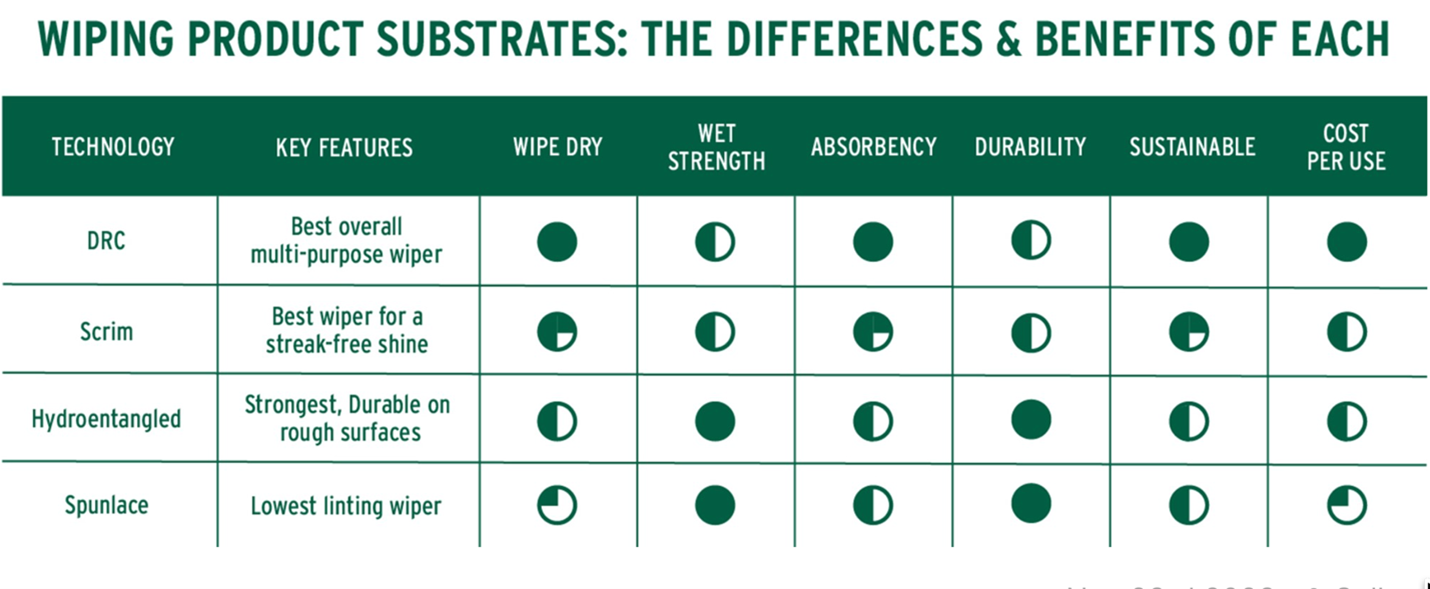

To choose the right wiper, review the tasks they will be used for, then identify a product substrate that has the right amount of wet/dry strength and absorbency.

- The Right Put-Ups

Next, choose the best put-up for your wipers. Wiper put-ups are the way in which sheets are dispensed. At Sellarsâ, we have several put-up options including quarterfold, center-pull box, center-pull roll, pop-up box, jumbo rolls, small rolls and Big Gripâ Dispensers. Learn more about these put-up types. Each dispensing option accommodates different applications and needs.

Put-ups that include a cardboard or plastic housing protect wipers from dust, debris and moisture while also improving portability. Jumbo rolls need to be refilled least often and can be mounted to the wall to free up manufacturing floor space. While all put-ups are useful, it’s important to choose the best one for your unique needs.

And put-ups can have a huge impact. Customers who switch from a quarterfold put-up to a perforated center-pull box use about 20% fewer sheets on average.

- The Right Locations

Location, location, location—true of both the housing market and wiping products. When an Operations Manager or General Manager places a wiping product in an area that commonly experiences messes, staff assumes that is the one they should use. Placing all wiping products in a central location can lead to staff taking more than they need to avoid another trip or cause them to choose a product that isn’t optimal for the task at hand. By identifying where and how wiping products are used, businesses can ensure the right products are always within arm’s reach for faster, more intuitive cleanups.

“Customer feedback plays an important role in our product development process. In fact, it has helped shape different products and put-ups that are on the market today,” said Rob Heglin, Senior Product Marketing Manager. “We are constantly working with customers to find the proper balance of wet/dry strength, absorbency, and surface compatibility for specific cleaning needs. And when done right, this means doing more while using less.”

Choosing the right wipers, put-ups and locations can allow businesses to clean up messes more efficiently while using less product and spending less. Searching for the right wipers (and the right substrates) for your unique needs? Browse our digital product catalog or contact one of our expert team members.

Recent Posts

-

Sellars Absorbent Materials Named BizTimes Milwaukee 2025 Small Business of the Year

Milwaukee, WI — Sellars Absorbent Materials has been named BizTimes Milwaukee’s 2025 Best in Busines …Feb 6th 2026 -

3 Ways to Use Less & Save More When Using Wiping Products

In many cases, less is more. This is especially true in the case of wiping products. Overuse is rare …Jan 26th 2026 -

How the Clean Task® Rebrand Helps Customers Find the Right Products for Each Job

Our customers are searching for wiping solutions for cleaning tasks—not just toolboxes. Yet, when pe …Nov 21st 2025