Scrim, Spunlace, Hydroentangled, DRC. What’s the Difference?

Wiping products come in a variety of shapes, sizes, colors, and substrates. So many choices may seem overwhelming but worry not! Choosing the best product and substrate for different applications is as simple as answering these three questions (no tricks—we promise).

- What is the wiping product being used for?

- What types of surfaces is the wiping product being used on?

- In what environment will you be using the wiping product?

In most cases, you can’t choose a “wrong” wiping product, but you may be able to choose a better one based on how and where it is used. A “better” choice may reduce the number of wipers needed to complete a task, the shine of the surface, and the lint (or lack of) remaining.

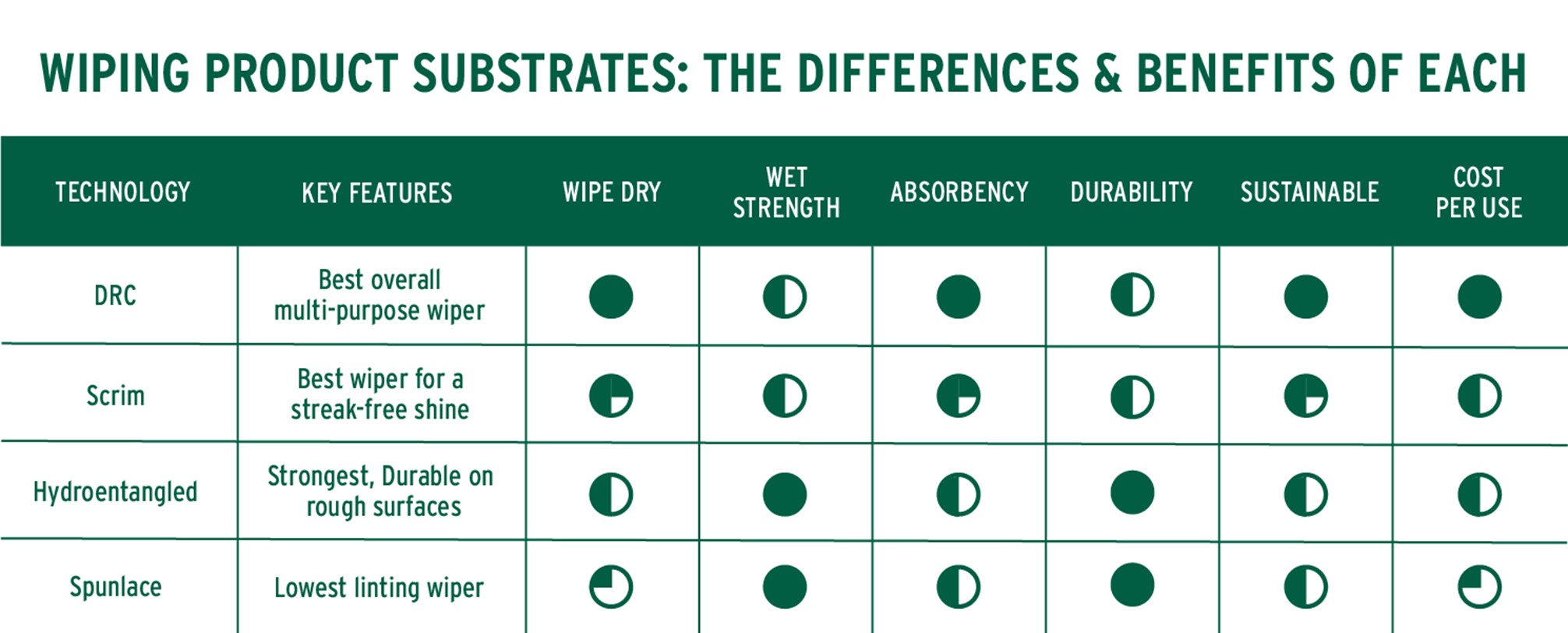

In this article, we’ll explain the different wiping product substrates and how they compare to one another in terms of durability, sustainability, absorbency, and wet/dry strength.

Double Re-Creped (DRC) Wipers

Double Re-Creped (DRC) wipers are our most sustainable wiper. In fact, Sellars is one of two manufacturers in the world using this propriety paper-based nonwoven process, which uses low-cost recycled fibers. But recycled fibers don’t mean compromised performance. Quite the opposite. Disposable, cellulose-based DRC wipers offer superior absorption, medium-strength durability, and is the strongest wipe dry substrate.

For general purpose cleaning and wiping, DRC is the overall best medium-duty, cost-per-use wiper for industrial manufacturing, education/government, healthcare, food service, automotive, and more. Plus, your business can earn LEED credits by choosing them. DRC wipers, like the TOOLBOX® Z400 GreenX series, are available in different strengths, styles, colors, and put-up types.

Hydroentangled

As its name suggests, hydroentangled wipers are made by using high pressure water jets to entangle polypropylene and cellulose fibers together. Hydroentangled wipers like TOOLBOX® WaterWeave® are the strongest wiper substrate, solvent compatible and lower-linting. This type of wiper is a great choice for industrial manufacturers that need a durable product that doesn’t degrade when used on rusted, uneven, or rough surfaces.

Scrim

A scrim wiping product is cellulose-based, made with a nylon “scrim” webbing that is then sandwiched in between 1-2 layers of tissue. Scrim wipers are incredibly soft, making them the best choice for smooth, delicate surfaces that require a streak-free shine. Customers in the detailing and automotive industries often seek a streak-free shine and a low linting wiper for window cleaning and overall polishing. A wiper like our TOOLBOX® R400 Scrim Wipers is a perfect choice for these applications.

Spunlace

Spunlace wipers have a key differentiator that may seem small but can have a huge impact on critical applications—lint. TOOLBOX® Spunlace Wipers are cloth-like and as low linting as they come. They’re ideal in printing plants, healthcare, aerospace, and electronics applications. Made from a web of fibers that are bonded together using water jets, spunlace wipers are durable, strong when wet, and solvent compatible.

When choosing a wiper substrate, it’s important to understand how it is used, on what types of surfaces and where and how it will be distributed. From there, it comes down to what feature is most important in your cleaning environment: absorbency, durability, sustainability, cost peruse, wet/dry strength.

Whatever wiping product you choose, Sellars has the right one for the job, any job.

Recent Posts

-

How the Clean Task® Rebrand Helps Customers Find the Right Products for Each Job

Our customers are searching for wiping solutions for cleaning tasks—not just toolboxes. Yet, when pe …Nov 21st 2025 -

Sellars to Showcase Clean Task and Celebrate 40 Years at ISSA Show North America 2025

Join us November 11–13 at the Mandalay Bay Convention Center in Las Vegas for the premier event in t …Nov 7th 2025 -

40 Years, 1 Booth, 3 Reasons to Visit Sellars at ISSA

It’s almost time for the biggest and best trade show of the year for the cleaning industry. The Sell …Oct 28th 2025